Vision

Vision

Transition to scalable ERS in three steps.

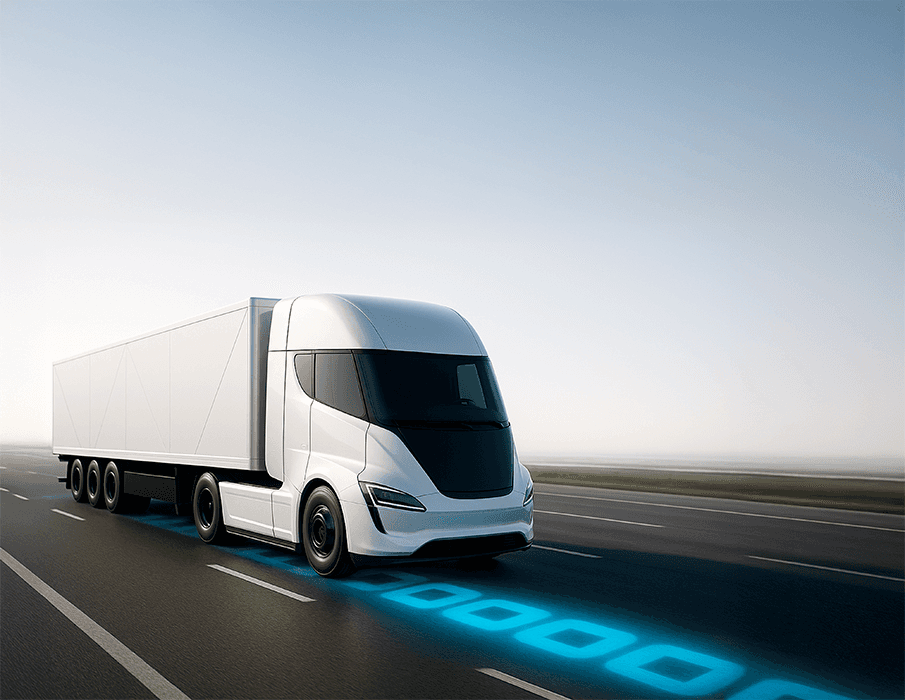

Driving the transition

to scalable electric road infrastructure.

Transition to scalable ERS in three steps

Transition to scalable ERS in three steps

Transition to scalable ERS in three steps

Driving the transition

to scalable electric road infrastructure.

Driving the transition

to scalable electric road infrastructure.

Michael Weigelt

CFO

Michael Weigelt

CFO

Maximilian Kneidl

CEO

Maximilian Kneidl

CEO

Michael Masuch

CTO

Michael Masuch

CTO

Applied expertise.

THE TEAM

THE TEAM

Research & Development

R & D

R & D

MFG

MFG

Manufacturing Experts

LOCATION

LOCATION

Here you can find us.

Karl-Martell-Straße 38

90431 Nürnberg

Germany

in our headquarter.

with precision.

in Germany.

in our headquarter.

with precision.

in Germany.

All made

STILL QUESTIONS?

STILL QUESTIONS?

Frequently asked questions.

What is Seamless Energy?

Seamless Energy is an innovative R&D company in the field of electric road systems. We enable scalable production of ERS.

What is the vision of Seamless Energy?

Our vision is to revoltionize transportation. We aim to integrate ERS across major routes by scalable production processes.

How does inductive charging work?

Inductive charging uses electromagnetic flieds to transfer energy. It allows vehicles to charge wirelessly while driving. The system is embedded in road infrastructure.

Is Seamless Energy collaborating with research institutions and universities?

Yes, we partner with leading research institutions. These collaborations drive technological advancements. Together, we innovate for a greener transport system.

How can i get in touch?

You can reach us via our website contact form. Our team responds promptly to inquires. Follow us on LinkedIn for updates.

Is Seamless Energy hiring new employees?

Yes, we are currently expanding our team. Check our career page for open positions. We seek passionate individuals to join our mission.

What is Seamless Energy?

Seamless Energy is an innovative R&D company in the field of electric road systems. We enable scalable production of ERS.

What is the vision of Seamless Energy?

Our vision is to revoltionize transportation. We aim to integrate ERS across major routes by scalable production processes.

How does inductive charging work?

Inductive charging uses electromagnetic flieds to transfer energy. It allows vehicles to charge wirelessly while driving. The system is embedded in road infrastructure.

Is Seamless Energy collaborating with research institutions and universities?

Yes, we partner with leading research institutions. These collaborations drive technological advancements. Together, we innovate for a greener transport system.

How can i get in touch?

You can reach us via our website contact form. Our team responds promptly to inquires. Follow us on LinkedIn for updates.

Is Seamless Energy hiring new employees?

Yes, we are currently expanding our team. Check our career page for open positions. We seek passionate individuals to join our mission.

CERTIFICATIONS

CERTIFICATIONS

Honored by the best.

PARTNERS

PARTNERS

PARTNERS

Stronger together.

Stronger together.

Latest highlights.

news

news

news

LOCATION

Here you can find us.

Karl-Martell-Straße 38

90431 Nürnberg

Germany

in our headquarter.

with precision.

in Germany.

All made

LOCATION

Here you can find us.

Karl-Martell-Straße 38

90431 Nürnberg

Germany

in our headquarter.

with precision.

in Germany.

All made

CERTIFICATIONS

Honored by the best.

CERTIFICATIONS

Honored by the best.

STILL QUESTIONS?

Frequently asked questions.

What is Seamless Energy?

Seamless Energy is an innovative R&D company in the field of electric road systems. We enable scalable production of ERS.

What is the vision of Seamless Energy?

Our vision is to revoltionize transportation. We aim to integrate ERS across major routes by scalable production processes.

How does inductive charging work?

Inductive charging uses electromagnetic flieds to transfer energy. It allows vehicles to charge wirelessly while driving. The system is embedded in road infrastructure.

Is Seamless Energy collaborating with research institutions and universities?

Yes, we partner with leading research institutions. These collaborations drive technological advancements. Together, we innovate for a greener transport system.

How can i get in touch?

You can reach us via our website contact form. Our team responds promptly to inquires. Follow us on LinkedIn for updates.

Is Seamless Energy hiring new employees?

Yes, we are currently expanding our team. Check our career page for open positions. We seek passionate individuals to join our mission.

STILL QUESTIONS?

Frequently asked questions.

What is Seamless Energy?

Seamless Energy is an innovative R&D company in the field of electric road systems. We enable scalable production of ERS.

What is the vision of Seamless Energy?

Our vision is to revoltionize transportation. We aim to integrate ERS across major routes by scalable production processes.

How does inductive charging work?

Inductive charging uses electromagnetic flieds to transfer energy. It allows vehicles to charge wirelessly while driving. The system is embedded in road infrastructure.

Is Seamless Energy collaborating with research institutions and universities?

Yes, we partner with leading research institutions. These collaborations drive technological advancements. Together, we innovate for a greener transport system.

How can i get in touch?

You can reach us via our website contact form. Our team responds promptly to inquires. Follow us on LinkedIn for updates.

Is Seamless Energy hiring new employees?

Yes, we are currently expanding our team. Check our career page for open positions. We seek passionate individuals to join our mission.